|

www.beadsbaublesandjewels.com |

| 1601-3 | Print | Close [X] |

| Barbara Lewis paints with fire to create her signature disc drive earrings. |

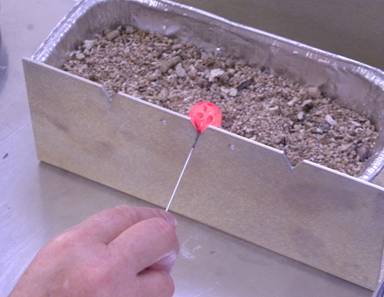

What makes the Painting with Fire technique of torch firing so special? I love teaching Painting with Fire (PWF) workshops because I get high off the enthusiasm of my students! Who wouldn’t love to see a stream of happy faces leave a workshop? Can you imagine enameling 50 beads in an afternoon as a rank beginner? How about enameling a bead in 40 seconds? No, I’m not crazy! It’s a simple technique and easy to learn. It’s also affordable because there are few tools involved and the ones needed are inexpensive. Let me walk you through the technique. The rest of the workstation looks like this … Put an iron or copper bead on the mandrel. Heat the bead in the flame. When it glows orange, immerse the bead in enamel and tap the mandrel on the side of the metal container to remove the excess enamel. Repeat the heating and dipping process two more times. Remove the bead by pulling it off the mandrel at the bead pulling station. That’s it! There’s no cleaning or pickling of the metal because the heat does that for us. No Klyr-fire or other fixative is necessary because the enamel immediately begins to fuse to the hot metal when the two come in contact. We’ve just eliminated two very time-consuming and tedious steps that are necessary in other types of torch firing. |

Barbara Lewis & Katie Hacker |