Project 202-1

The Cloisonné process: Making beads,

pendants and objects of art.

By Doreen Stephens

Researchers agree the Cloisonné technique originated in Egypt

prior to 1800 B.C., beginning with gold ornaments inlaid with small pieces

of genuine gemstones. Speculation is, eventually goldsmiths and glass

workers collaborated to imitate these works using pieces of colored glass

substituted for stones.

It is believed that the technique reached China through missionaries from

central Asia sometime in early to mid-14th Century A.D. Shortly after

its introduction, the Chinese made cloisonné enameling a truly

distinctive art form by mastering the skill of manufacturing and constantly

improving the technique. The main reason for their stunning achievement

is due to the fact that the Chinese nation already had the technology,

such as casting, glass and glaze production, enabling the artisans to

accurately control the firing and temperature for the enameling process.

The word Cloisonné is a French word meaning to be compartmentalized

or be cut off from one another.

The word cloisonné is used to identify the technique, as well as

the finished product. A technique relative is filigree - where wires are

soldered in patterns to a background. Another variation is plique a jour,

known as backless cloisonné.

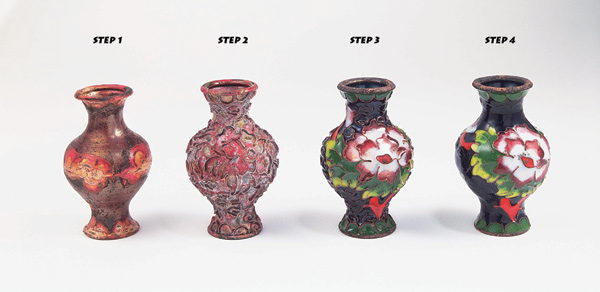

The Cloisonné process

- Creation of shape from Brass or copper

- Shaping and soldering on of enamel cell shapes in patterns covering surface . The wires used are made of copper.

- Initial fill of cells with multi colors of enamel, fire in kiln. Each step is created by an artisan in that expertise.

- When firing, the enamel contracts, so more color fill is needed - 3 to 4 times until the surface is even, smooth and without depressions. The enamel here still looks glossy.

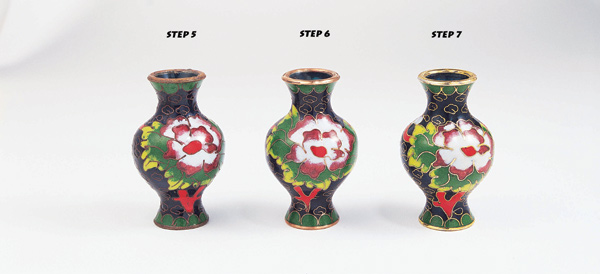

- Sand and polish surface so level and uniform. Cells and enamel should look melded into one. You’ll notice the finish is dull at this point. It still must be polished.

- Polish... and Coat with electro-plating medium as prep for metallic accenting. Electroplate outer portion of cells and any other desired areas.

- Final polish and cleaning. . A bead can take 5 hours from start to finish, something like the vessel can take a week.

Quality Cloisonné must have colors that are glossy and bright,

a body that is sturdy, and wire inlay that is neat and well proportioned.